SYSTEM 製品システム

Coating

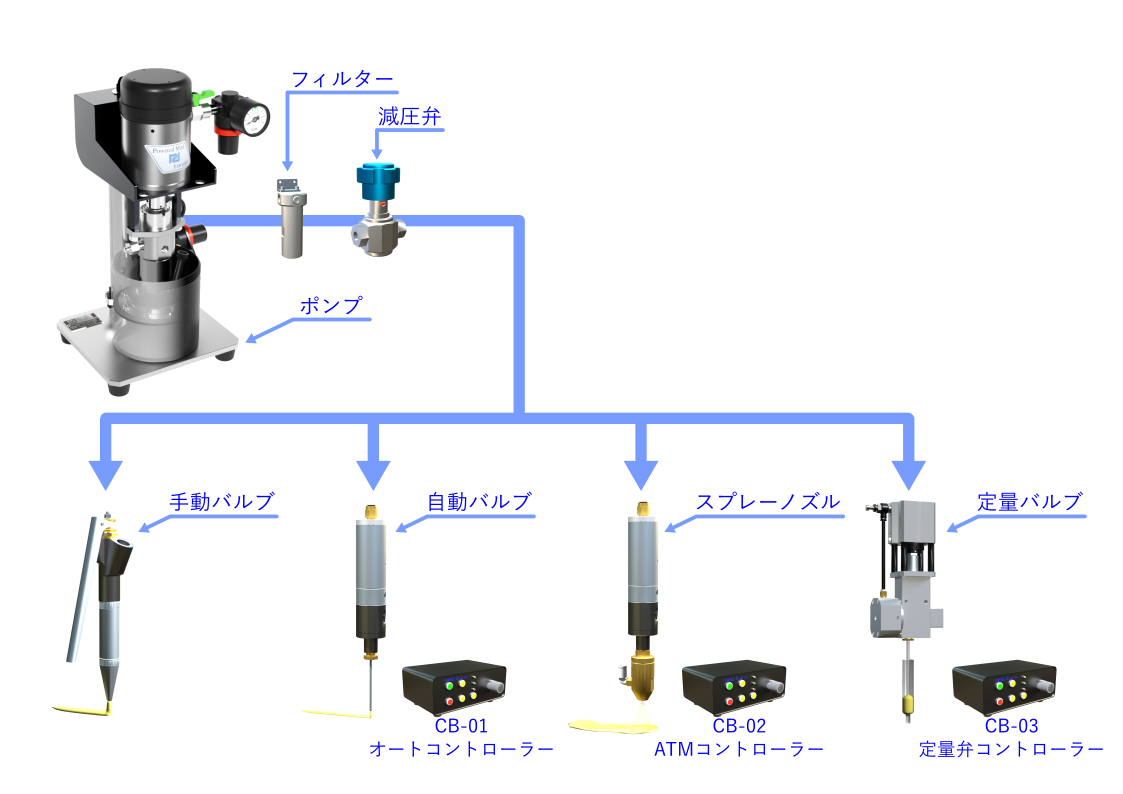

This figure shows the basic system configuration.

Equipment with these basic functions performs point dispensing, line dispensing, and spray dispensing of high-viscosity materials. We will propose the most suitable system for a variety of materials. Automatic dispensing of workpieces using robots is also available upon request.

ー Materials used ー Greases, sealants, adhesives, FIPG (liquid gaskets), heat dissipation compounds, etc.

Filling

We manufacture high-precision filling systems utilizing our accumulated technologies.

Past results

- Printer ink cartridges

- Various types of dampers (automobiles, fittings, musical instruments, etc.)

- Various kinds of materials (grease, sealant, silicone oil, etc.)

Especially in the filling of silicone oil, our patented technology has realized a filling rate approaching 100% with no air bubbles during the filling process. We can automate the entire process from container filling to closure (e.g., stoppering, capping, etc.), transportation, and inspection by completely custom-made systems.

2- or 3-component metered dose dispensing

Our LSR (liquid silicone rubber) metering machines can handle high viscosities exceeding 4,000 Pa-s. We can manufacture small to large capacity metering machines, from laboratory to mass production, in various specifications such as docking to LIM (thermosetting liquid material injection molding) molding machines, pneumatic, hydraulic, and electric types, etc., completely custom-made to order.

Ink supply equipment

Offset Ink Supply System

Our pumps supply ink to newspaper printing presses.We design the system according to the requirements of newspaper publishers and provide after-sales service for long-term use.

Automatic Vacuum Recovery System for Waste Liquid (Utility Model)

Automatically collects waste ink from ink rollers and blanket cylinders.Waste liquid in the waste liquid collection pan after washing is automatically collected at any time after the end of printing, reducing the frequency of cleaning work for each waste liquid collection pan.

Pure Water Production System

The ROX4500 uses reverse osmosis (RO = Reverse Osmosis) to produce pure water (purity level 3-10 μS/cm). It is expected to improve and stabilize printing quality, reduce the amount of water, H-liquid, ink, paper waste, and VOCs, and reduce spray bar nozzle clogging

Our Strengths

All equipment is manufactured in-house. We take full responsibility for after-sales service even after decades of use. We also provide prompt emergency response in case of breakdowns. Our pumps have been used in various industries and are highly regarded for their low maintenance frequency.

metered dose dispensing Ink supply

equipment